✢ 2024 ✢

Industrial Design

Portfolio

by

Daniel Summers

I am an industrial designer based in the Minneapolis area.

About me

Daniel Summers

Skills

Education

Employment

DePaul University

School of Design

Bachelors of Fine Arts

Industrial Design

(2020-2024)

Lab manager

Idea Realization Lab

DePaul university

(2021-Present)

Design Intern

Dunsel’s Sailbags

(Summer 2023)

Adobe Suite

Solidworks

Rhino 7

Keyshot

Sketching

Ideation

Fabrication/Machine Knowledge

I am passionate about all aspects of industrial design and consider myself well-rounded in all fields, particularly footwear design, soft goods, and novelties/games.

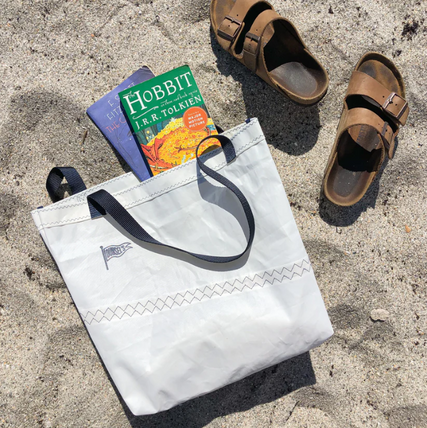

Design Internship W/ Dunsel’s sailbags

I had the privilege of joining Dunsel’s sailbags for a summer design internship. My assignment was to assist the design team in re-designing their “Classic Tote”.

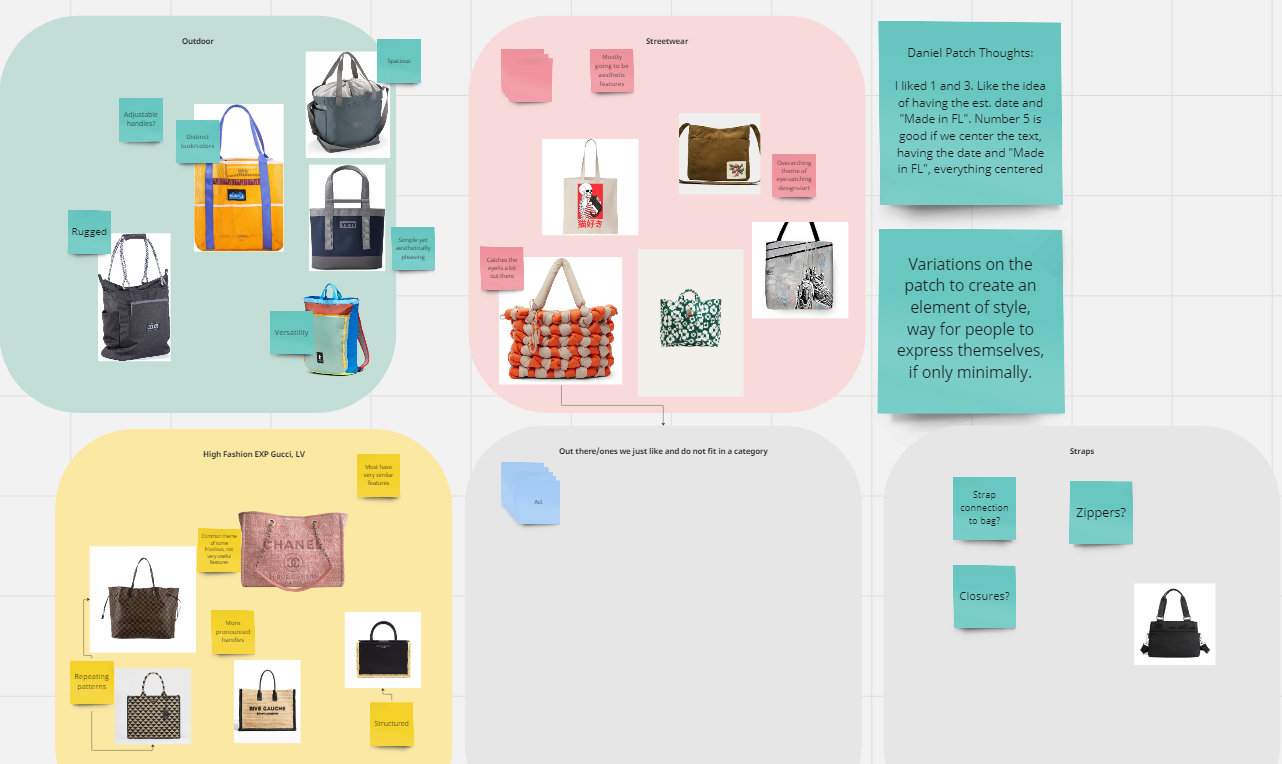

Research

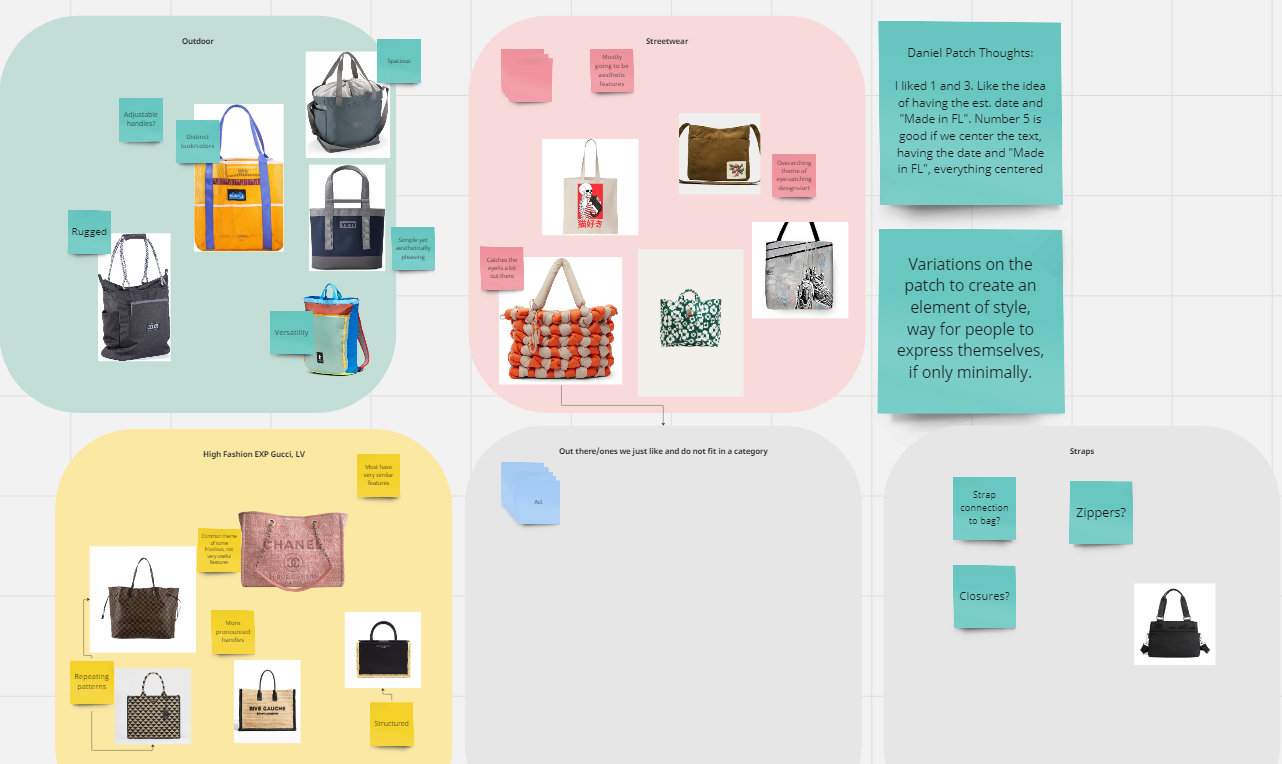

As mentioned, Dunsel’s wanted to re-design their “classic tote”. The goal was to give their tote more desirable features, so as to better help it compete on the market with other bag companies.

We started by researching other tote bags on the market, and what features seemed to make them unique and/or useful.

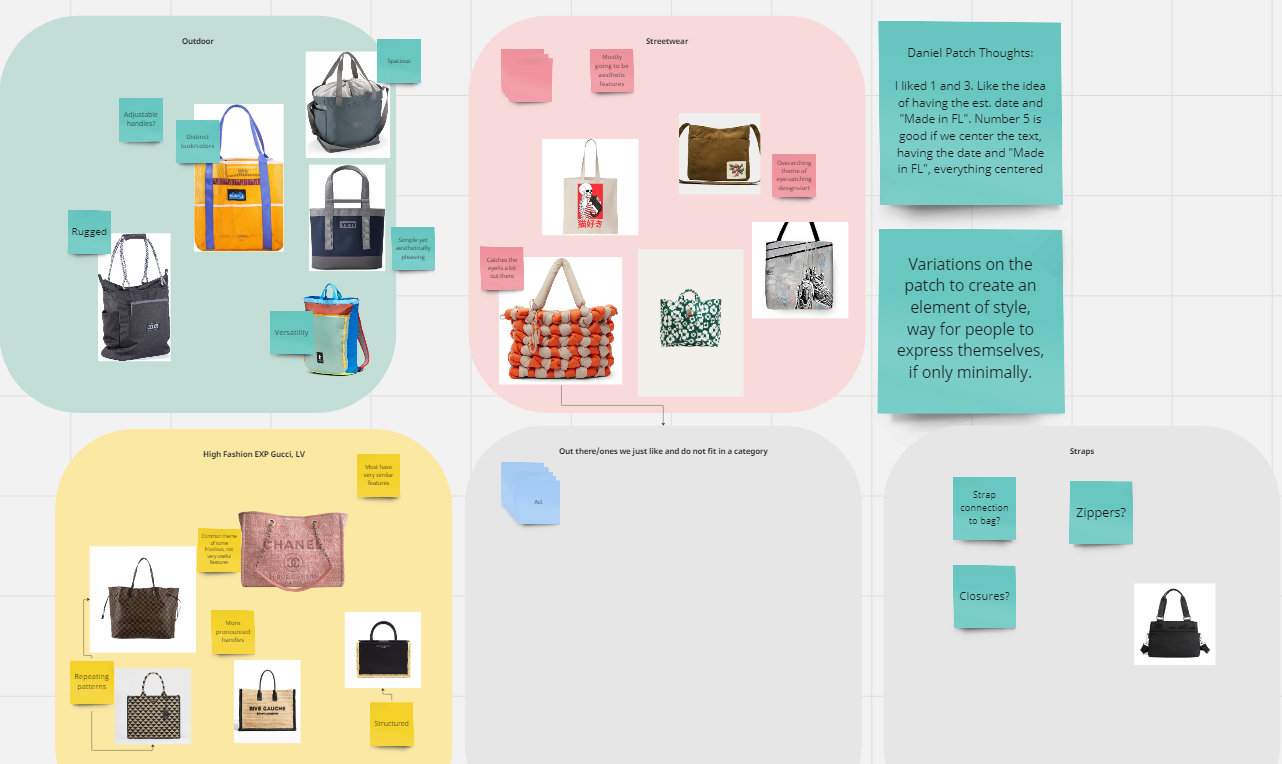

From there, I drew up some thumbnail sketches of what some of these features might look like in different combinations, and with different shapes of bags.

Sketching

From there, I drew up some thumbnail sketches of what some of these features might look like in different combinations, and with different shapes of bags.

Ideation/

Prototyping

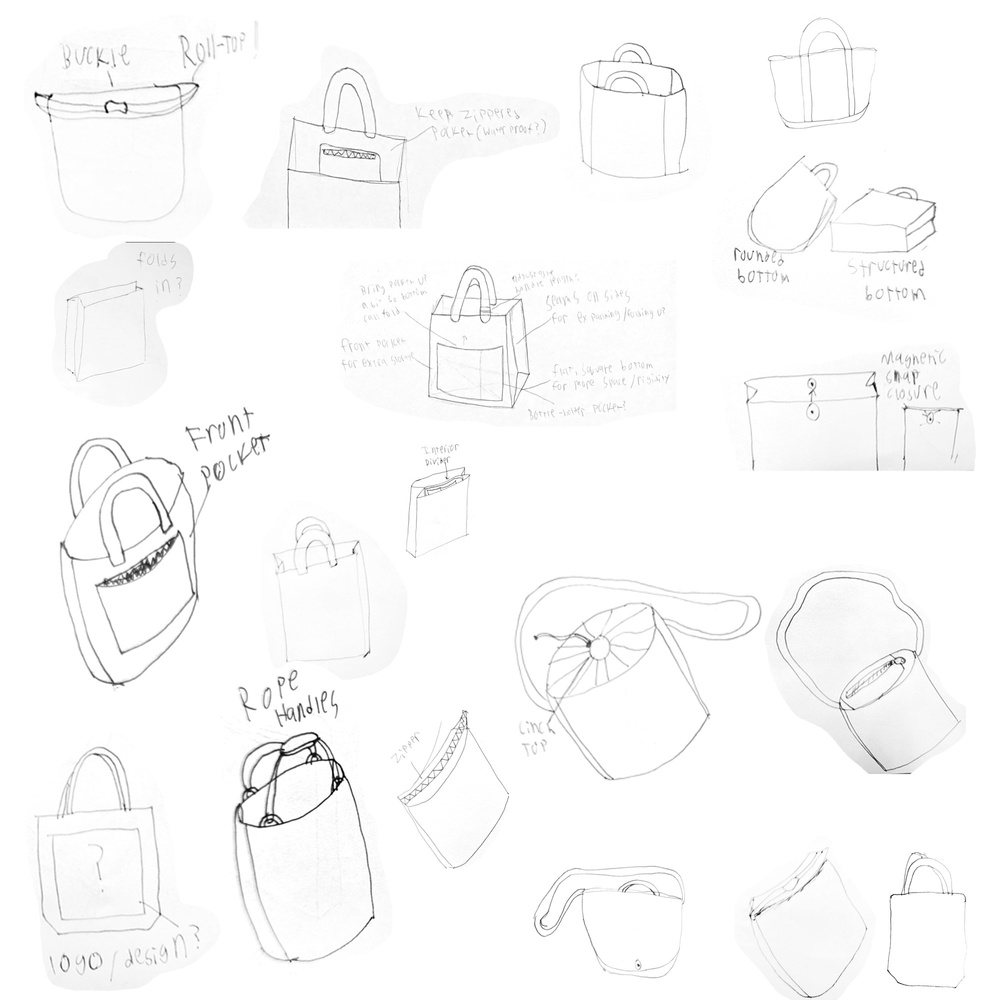

After getting a better idea of some of our options and what they may look like, we narrowed down what features we wanted to include, and had a few more sketches and started prototyping.

We decided we wanted an over the shoulder strap, and maybe short handle straps as well. We decided on an internal pocket, but hadn’t quite narrowed down if we wanted a divider of sorts, or just a pocket. Finally, we decided we wanted to add color to the bag, as many competitors offers had it.

Final product

For our final design, we decided on having both types of straps to allow for more versatility. We also decided on having an inner divider with a zippered pocket, to allow the user to better organize the things they carried. Lastly, we decided to add patches of colored marine webbing to give it a more noticeable look, while still using sustainably sourced material from the boating industry.

The finished product took the “Classic Tote” from a blank, simple bag, to a colorful, versatile, and utilitarian tote that gives potential customers much more reason to purchase it.

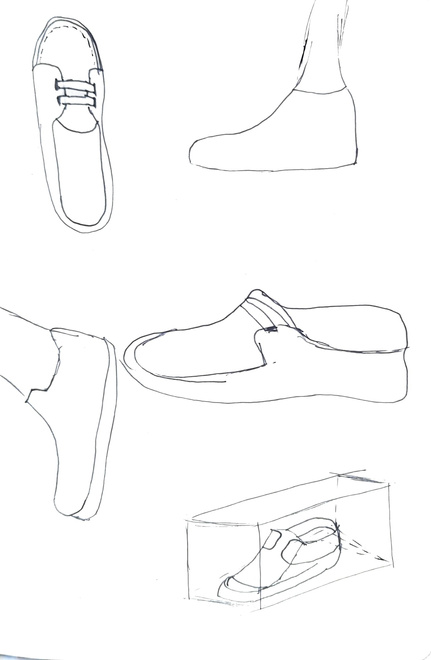

Zephyr shoes

A sustainable boat shoe made from recycled sailcloth. Designed for a studio course focused on sustainability

Research/

Sketching

For this project, we were asked to define a client, and create a product for said client that followed sustainable practices.

I knew that I wanted to use recycled sailcloth in some capacity to make footwear, as I had an abundance of it on hand, and it fit the idea of sustainability perfectly.

After some research, the client my partner and I decided on was boaters. Who better to use a product made from recycled sails?

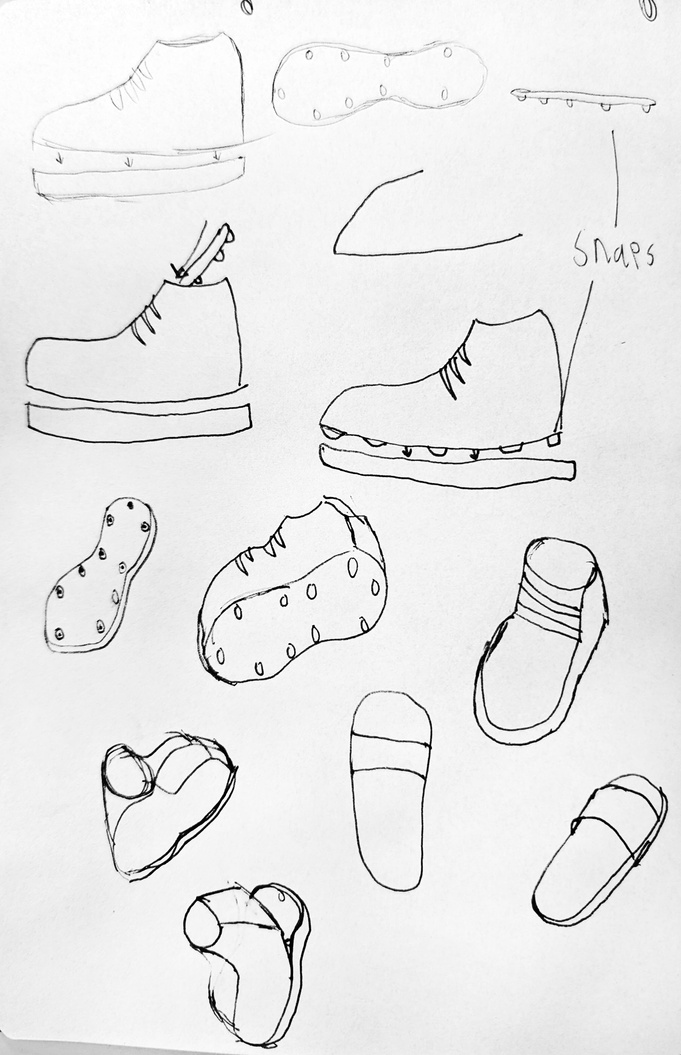

Once this was decided, we got to work sketching out possible shapes/forms for the boat shoe.

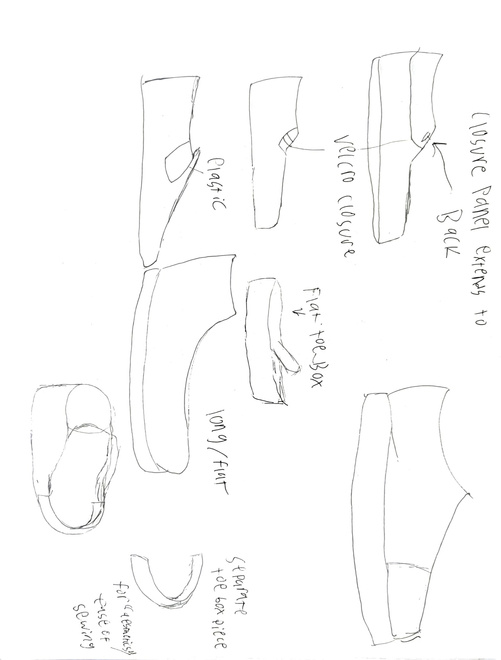

Prototyping/

Refinement

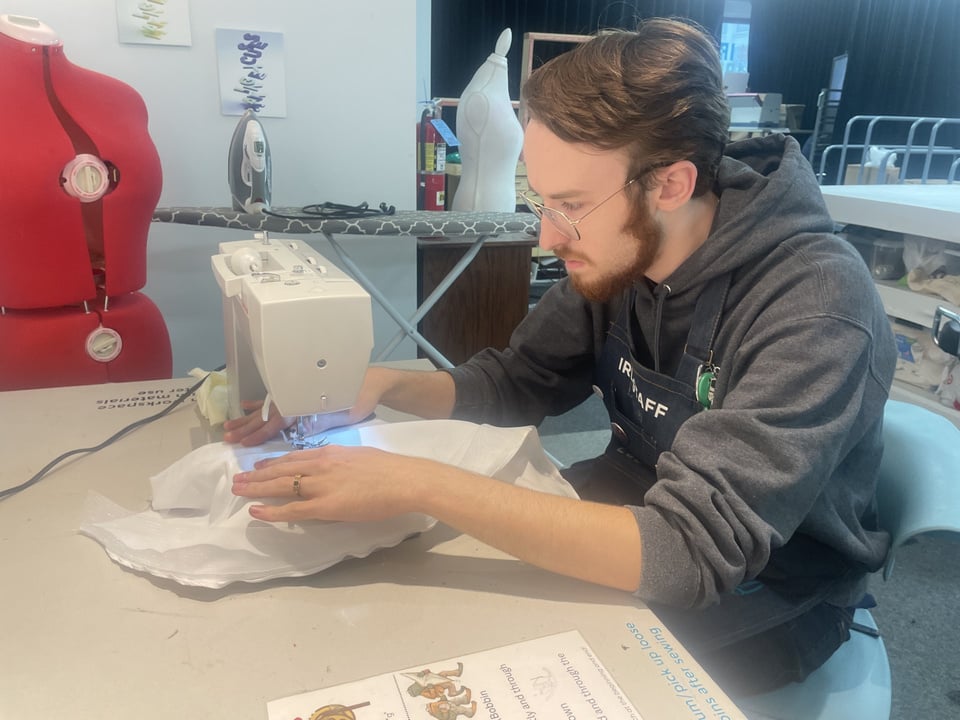

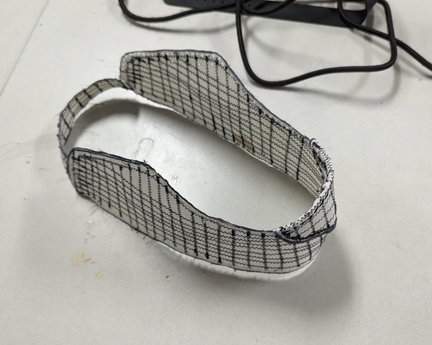

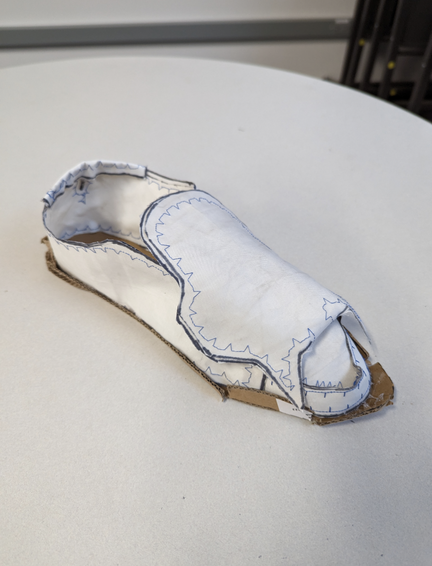

Once we had some sketches completed, we moved on to making some physical prototypes for the shoe.

To get some experience making footwear from scratch, I started off by following a pattern I found online. This allowed me to gain a better understanding of how typical shoes were cut/assembled.

From there, I moved on to making my own shoe without a pattern. I tried quilting the fabric with stitching to add some rigidity, but this interfered with the ability of the sailcloth to form the way I wanted it to.

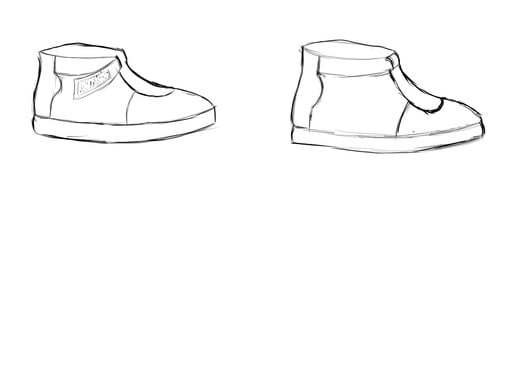

Final product

We ended up with a low-profile, comfortable, and durable shoe that was low in environmental footprint, but high in utility.

We decided on colors that we believed fit the sailing aesthetic, as well as a Velcro closure that not only allowed for the shoe to be put on/taken off easily, but also allowed us to use parts from the sail for the closure, rather than adding new materials.

Swap-ped

A modular pair of shoes designed last, while also reducing textile waste.

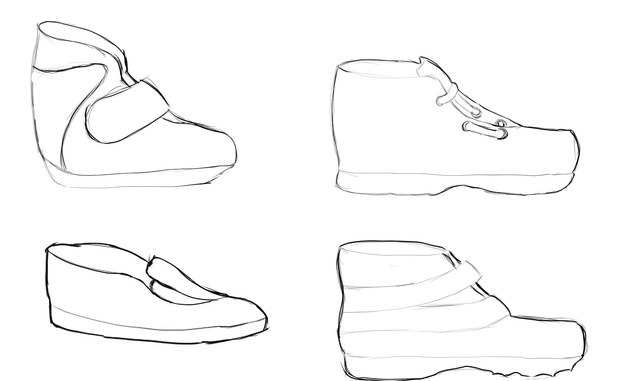

research/

Sketching

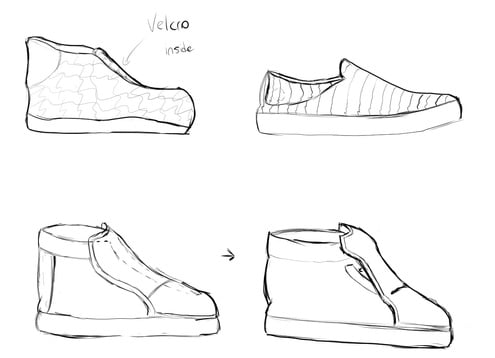

I started by doing some research into potential existing iterations of modular footwear to see what might already be on the market, and get some inspiration.

One of the main reasons the footwear industry produces so much waste is because of the fact that footwear is often made from multiple materials that are difficult to separate, making it difficult to recycle said materials properly.

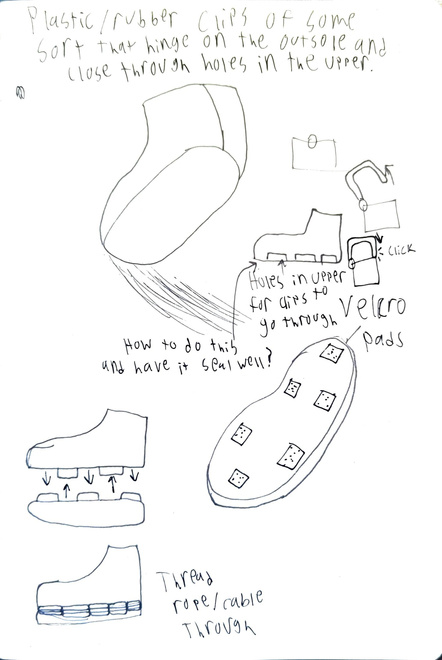

In my research I found a few modular pairs of footwear, but most of them still had this issue of using multiple materials, like attaching zippers of plastic clips.

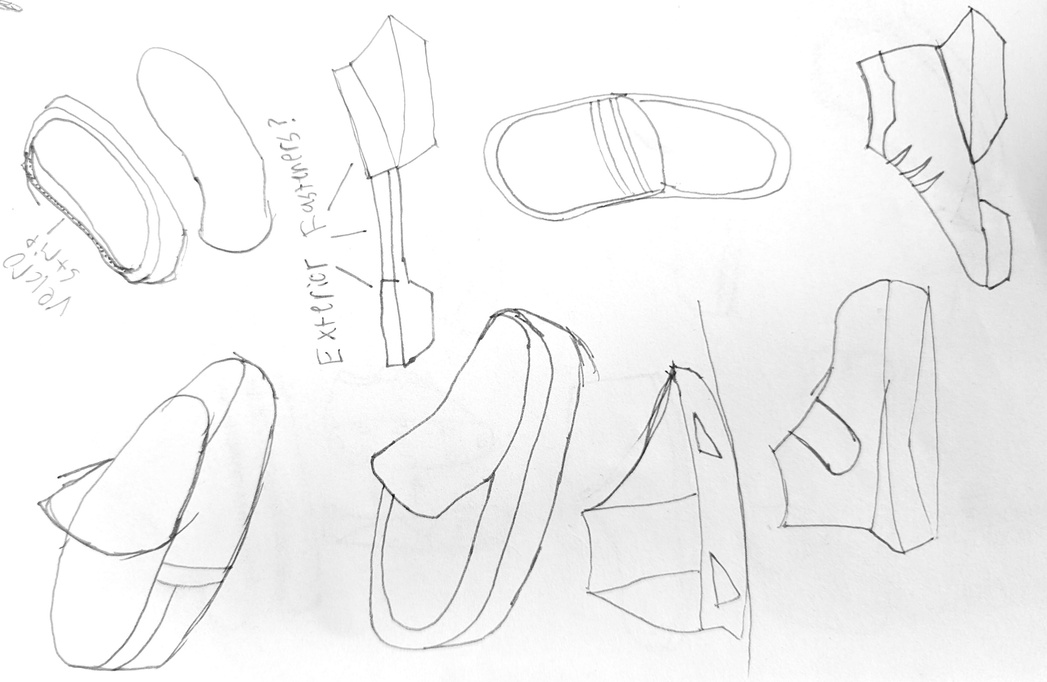

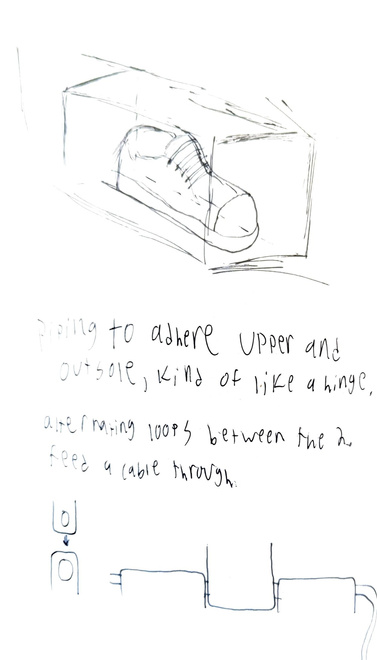

I got to work sketching out some potential designs that would allow the upper and sole of my shoes to be attached in a way that they could be separated without too much hassle, and would allow for easy recycling

Sketches Cont.

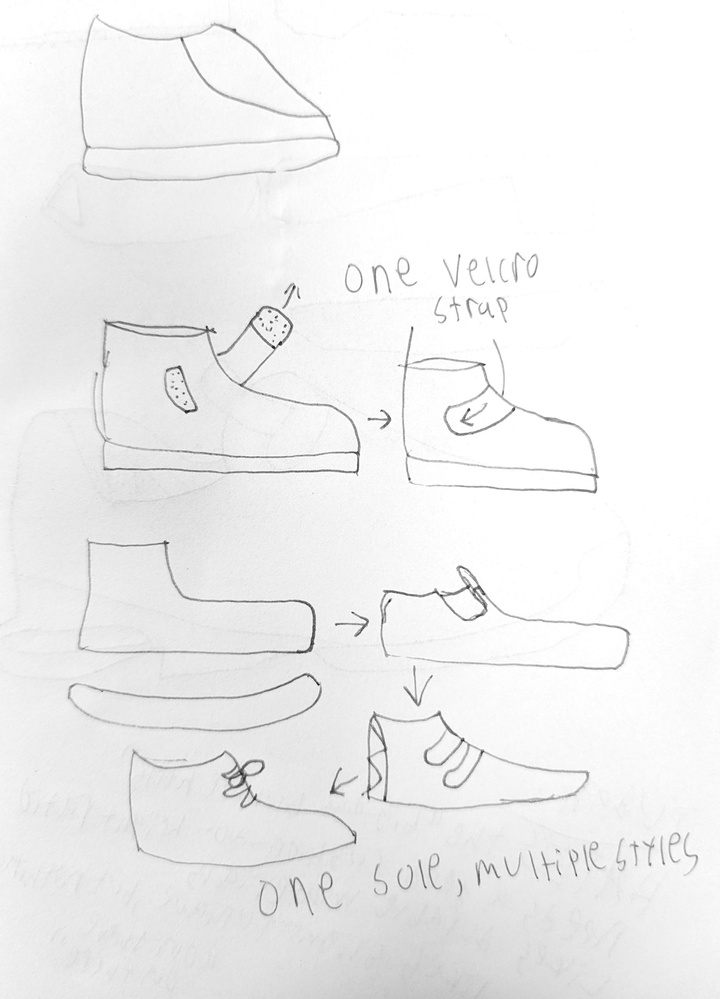

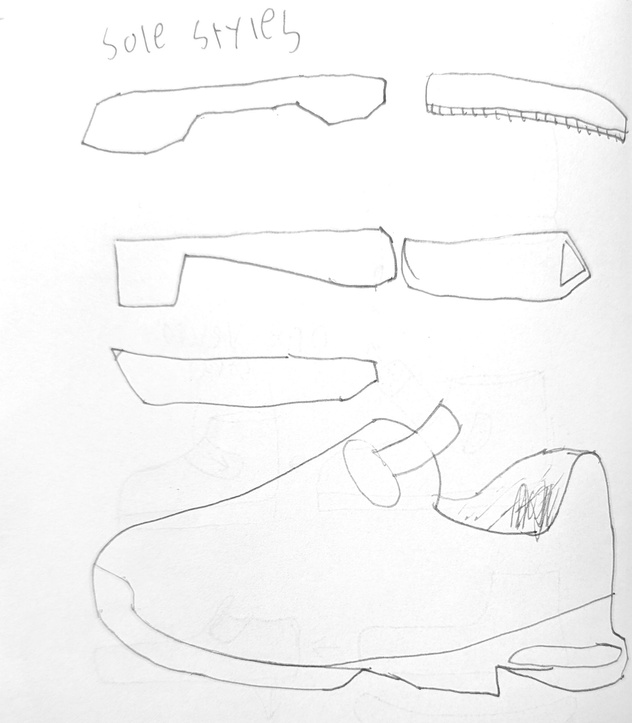

The design

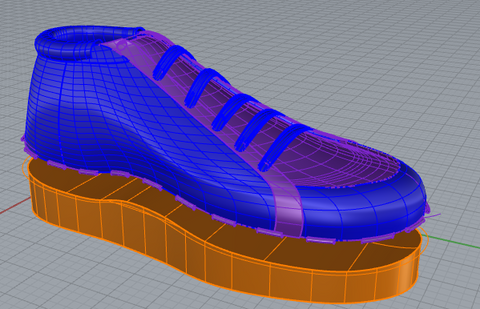

I decided on a system of fabric loops going around the upper of the shoe, and rubber loops going around the sole of the shoe. This way, the upper and sole could be connected by threading a cord through the loops, and each part of the shoe would still be easy to recycle.

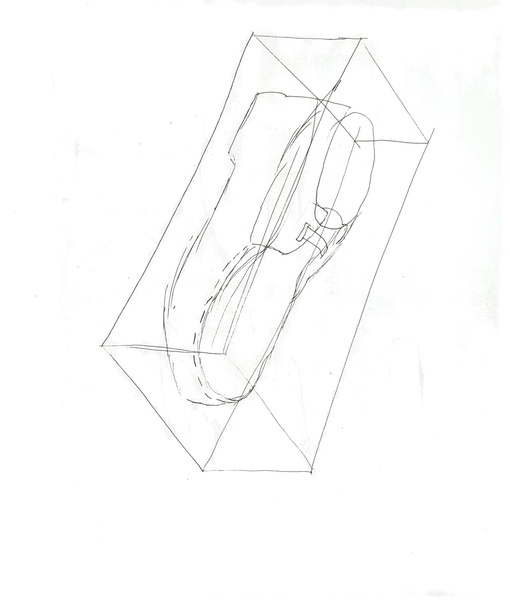

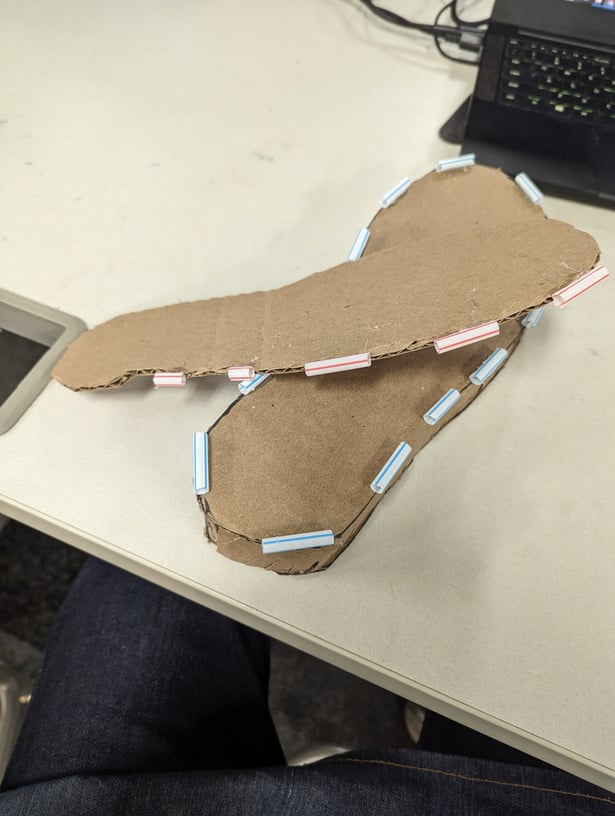

Once I decided on this form for the shoe, I tested it’s functionality through a low-fidelity cardboard prototype, and then got to work modeling the shoe in Rhino 7.

Finished Product

The final deliverable for this project was a model created in Rhino 7 that I textured and created product renders of in Keyshot.

Collaboration With Stern Pinball

A class project with Stern Pinball in which we designed a Wu-Tang Clan themed pinball playfield.

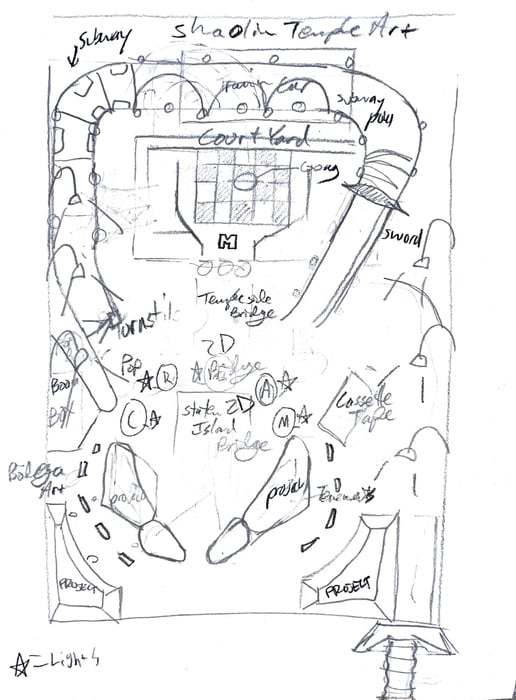

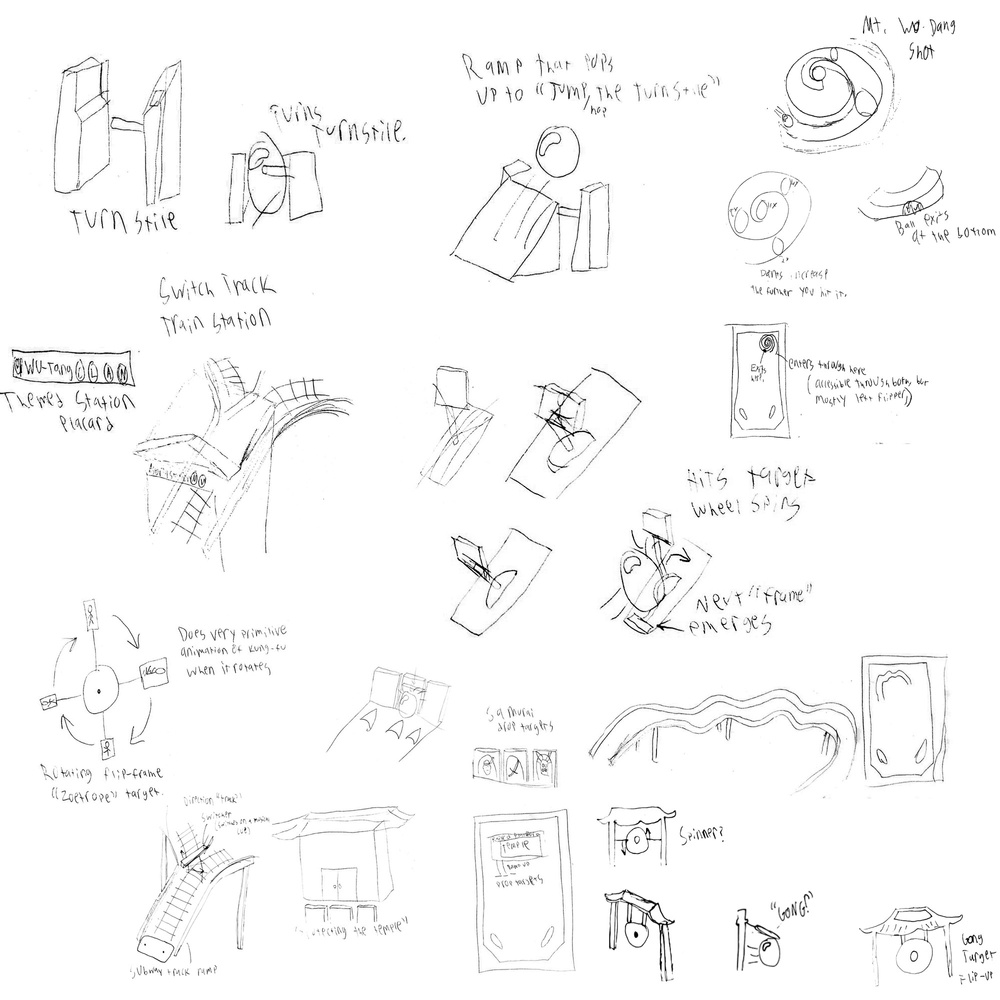

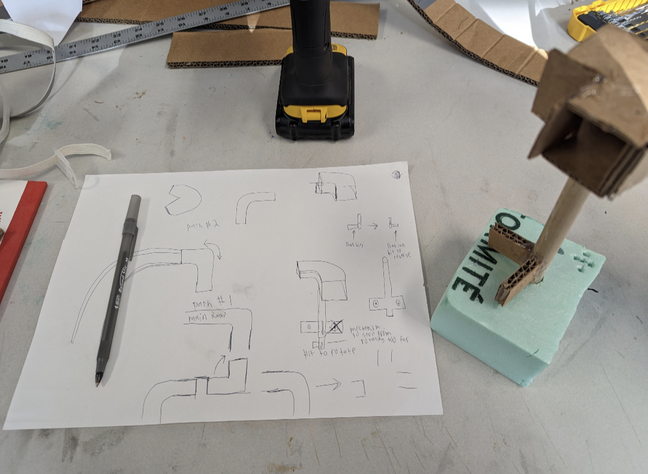

Sketching

We started by sketching our ideas for fixtures on the playfield. We wanted to create features that would combine fun game mechanics with references to the culture that permeates the Wu Tang Clan.

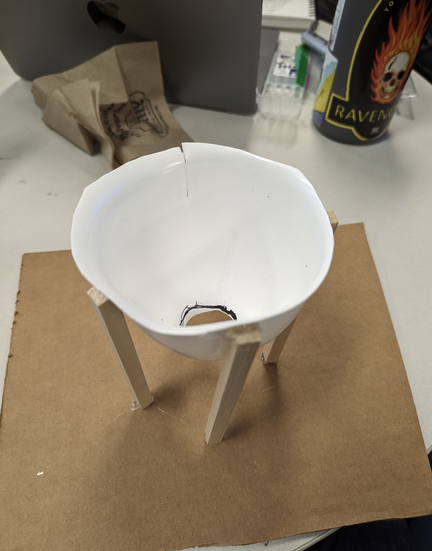

Research and prototyping

Our class was fortunate enough to be given a tour of the Stern Pinball’s factory and design studio. This, combined with talks with the designers, was instrumental in us forming our early designs.

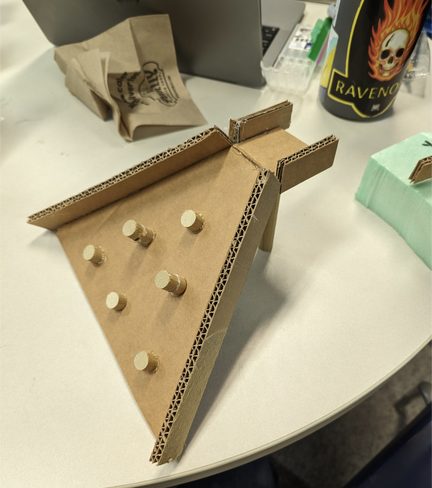

After this tour, we began making some physical prototypes for potential features we’d like to put on the board. Fortunately we were given a machine with a blank playfield, as well as many pre-existing features that tend to be standard across most pinball machines.

Our goal during this phase was to take some of the ideas we’d generated and see if they’d be viable options

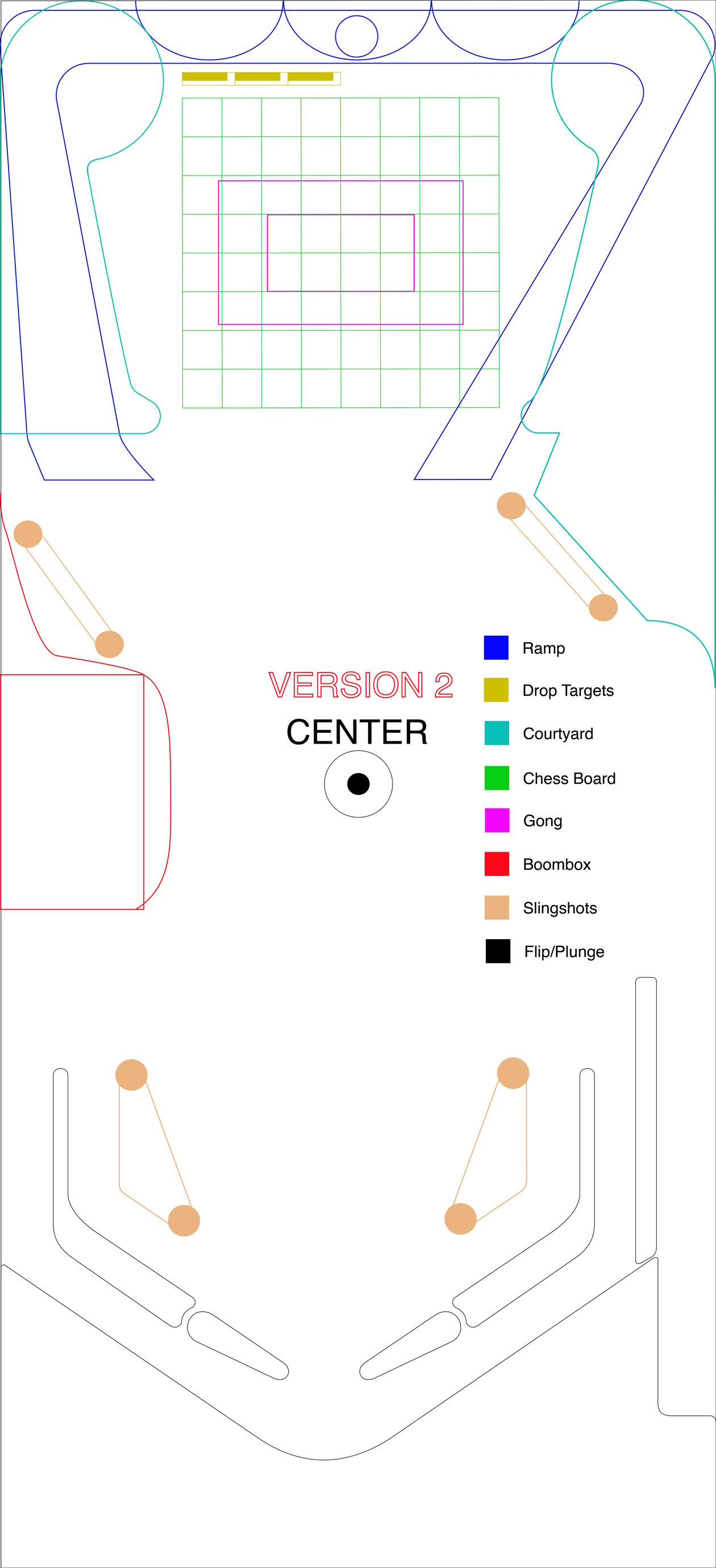

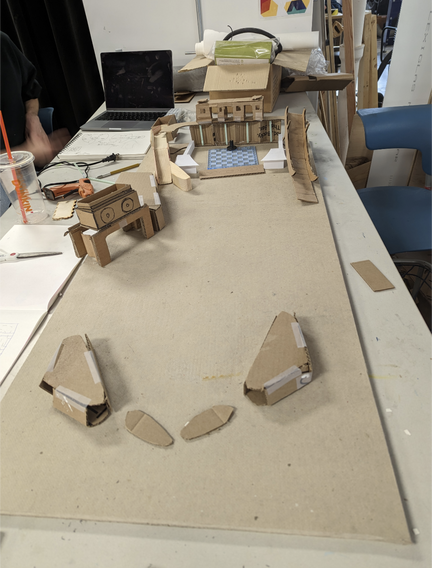

playfield layout

Our next step was to begin narrowing down our features and deciding how best to arrange them on the playfield to create the most engaging pinball experience.

Figuring out the flow of the features was arguably the most difficult part of this project. You want the game to be easy enough that anyone can play it and have a good time, but also hard enough that the more dedicated players will want to keep playing and challenging themselves for higher scores.

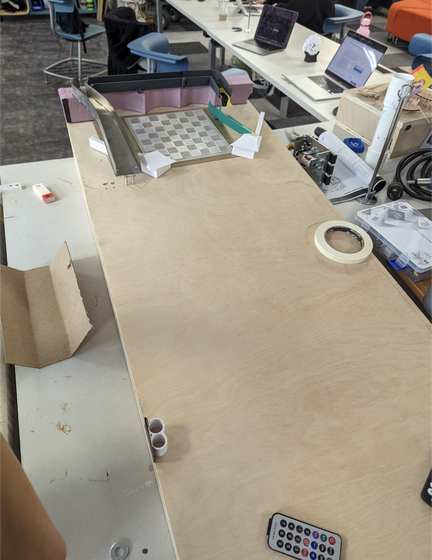

Final Product

Once we had decided where we wanted our features to go, all that was left was to put them on the playfield.

We ended up with fewer features than we had originally hoped for due, in part, to the short-form nature of the quarter system at DePaul. Still, I was happy with the features we were able to get to function.

We were able to get a functioning subway-themed ramp that fed the right flipper, a functioning pop bumper with a printed boombox, 3 “samurai” drop targets that opened the playfield into a more challenging area, as well as some themed art.

work

with me

phone

763-445-0051

e-mail

dasumm02@gmail.com